Food Industry X

Company name protected by contractual confidentiality clause.

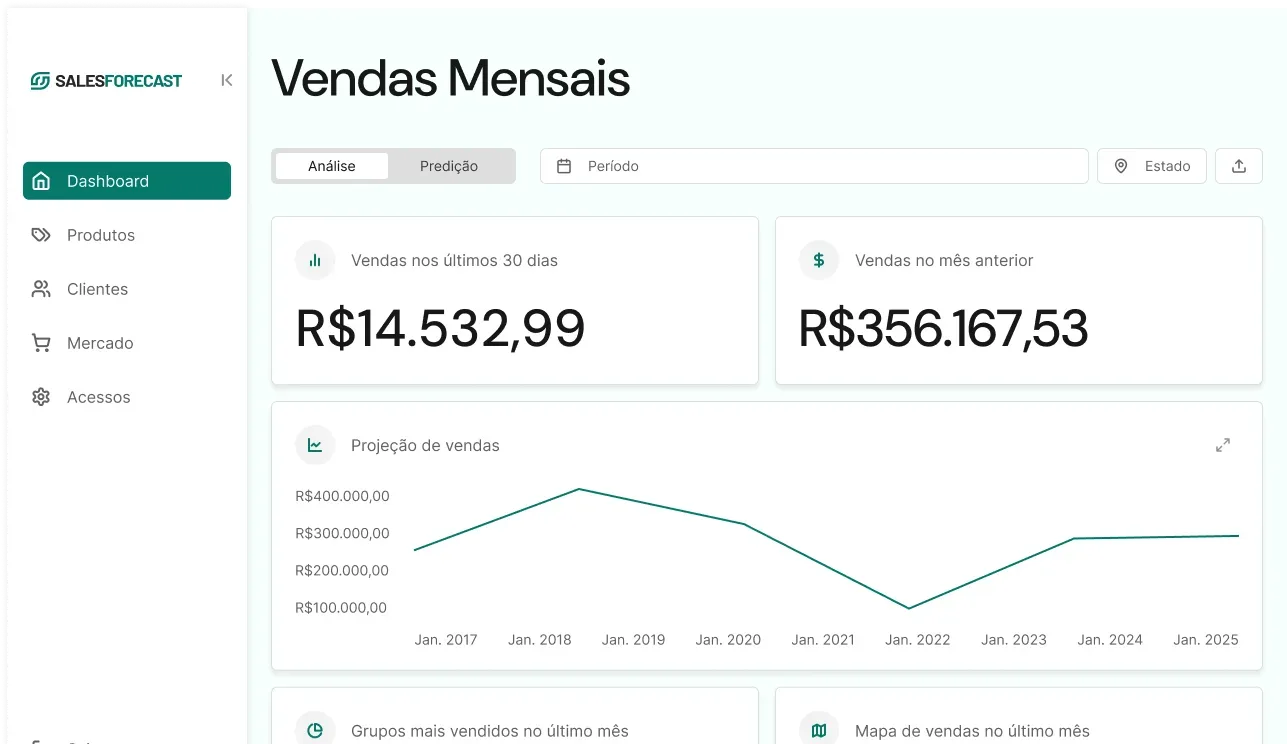

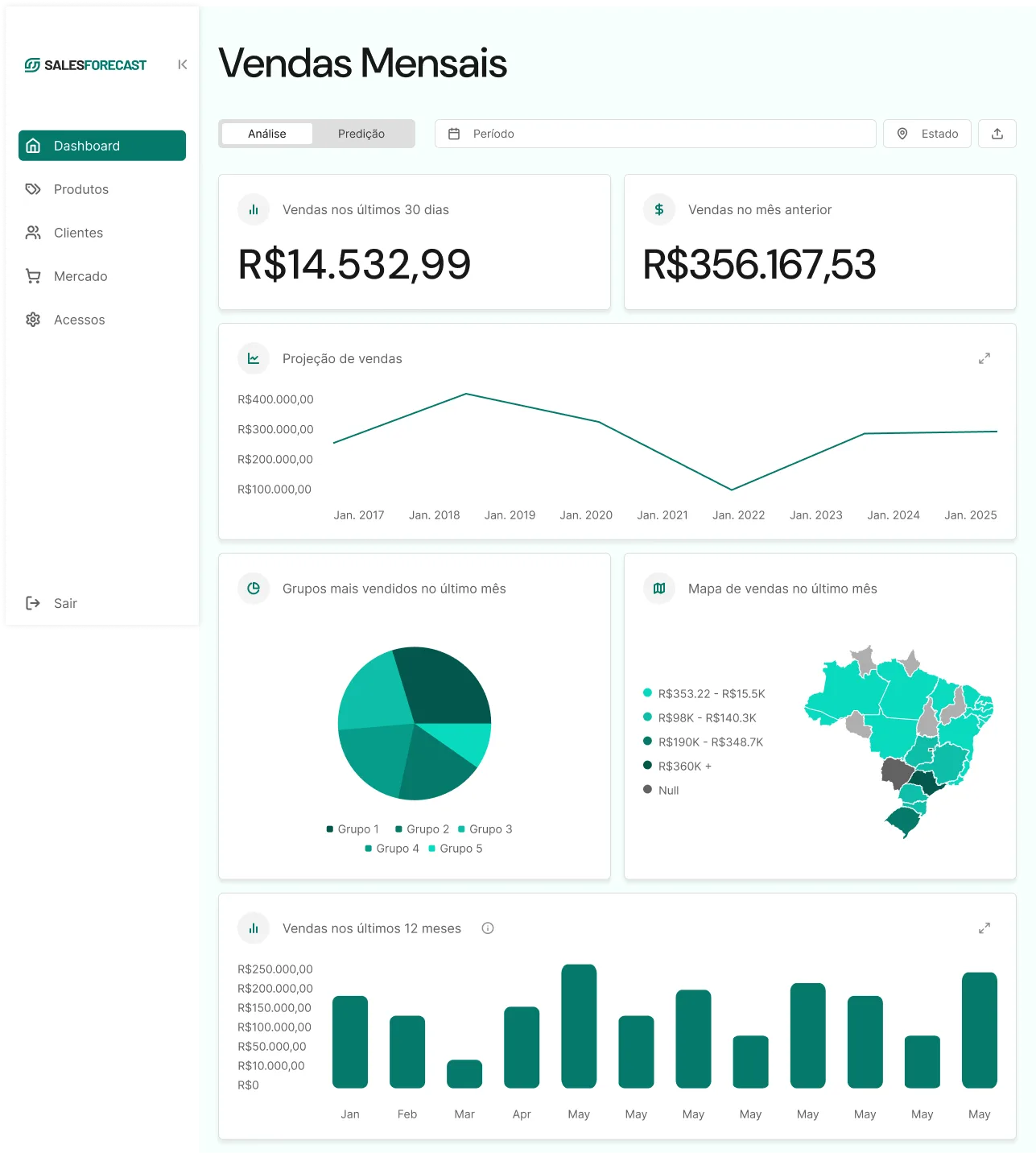

We know that a lack of visibility leads to losses. When Sales, Distribution, and Logistics don't work together, the result is stockouts or excess seasonal products. Our Sales Forecast system provides integrated control of your demand, connecting external data (weather, local events, media) to your orders and ERP. With accurate forecasts, you know the right time to allocate inventory, adjust production, and set targets.

And, of course, align your teams, automate recommendations, and manage the entire supply chain on a single platform.

Challenge

Planning was fragmented between the Sales (salespeople/representatives), Distribution (regional distributors) and PPC/Logistics areas, making it difficult to have an integrated view of the operation.

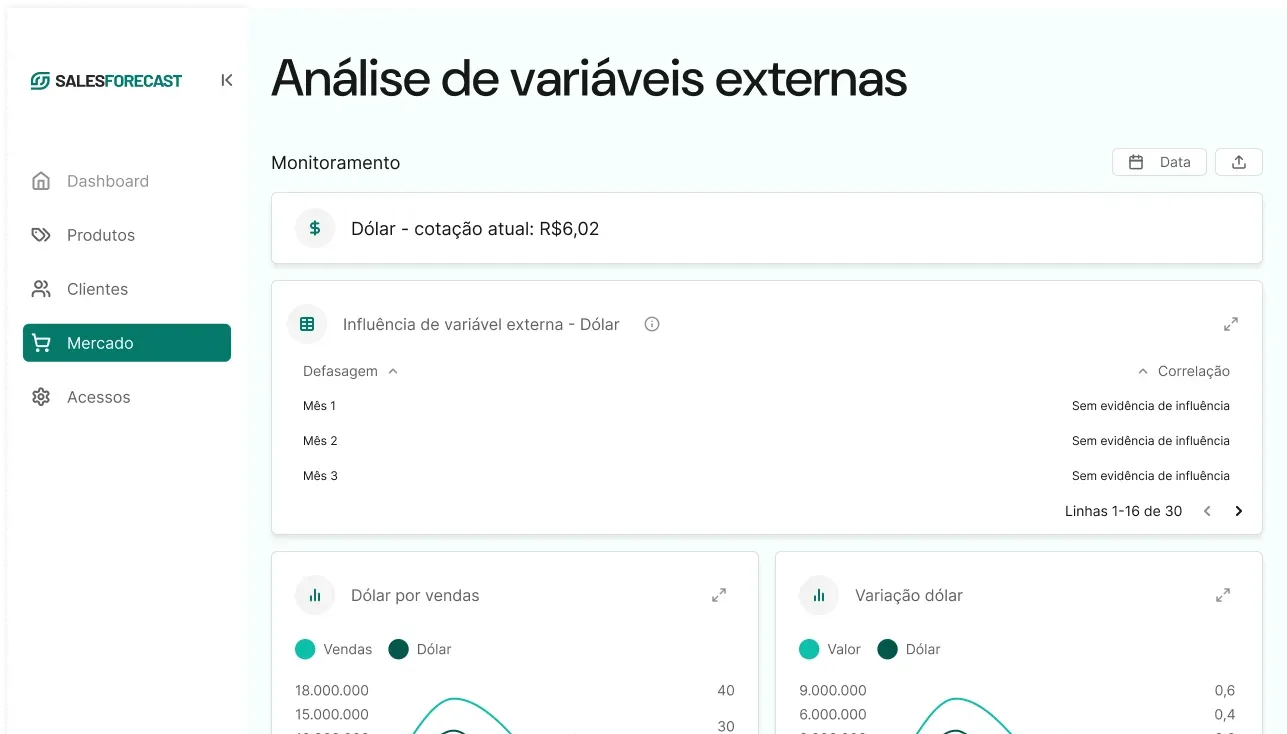

Decisions were based solely on history and local perception, without integrating critical external variables such as weather, promotional calendar, media, purchasing power by location, and events.

Side effect: mismatch between supply and demand, pressure on margins and low predictability of turnover at the POS.

Solution

The system uses predictive models and Artificial Intelligence (AI) powered by a combination of internal data and, crucially, multiple layers of external data.

How Sales Forecast Works

Climate: It incorporates local weather forecasts (temperature, rainfall) that affect consumption.

Calendar: It takes into account holidays, regional events, payment dates, and retail promotions.

Market: It analyzes consumer signals, such as economic indicators, online searches, and in-store traffic.

AI (Learning): It automatically calibrates forecasts by SKU and channel, learning from new data.

AI (Analytics): It explains the impact of each variable (climate, price) and simulates "what if?" scenarios.

Unified Data Lake: A framework that integrates and organizes all data (historical and external) to feed the AI.

Operational recommendations generated by the model: salesperson / representative:

Sell-out targets and forecast by portfolio.

Warnings of imminent rupture.

Mix suggested by POS.

By distributor:

Optimal allocation by distribution center/route.

Target coverage and replacement policy per window.

Possibility of VMI (Vendor-Managed Inventory) models with reliable sales and inventory data at the POS.

By channel:

Turnover forecast and purchase recommendation by period.

“What if?” scenario simulations.

Results obtained

Reduction in average inventory, freeing up capital and reducing maturity risk.

Reduction of stockouts in strategic SKUs, ensuring constant availability at the POS.

Increase in operating margin.

Synchronized planning by cluster, channel and portfolio, uniting sellers, representatives and distributors around realistic forecasts.

Differential perceived by the sales team and partners

Salesperson/Representative:

Agenda prioritized by potential and risk. Mix and volume by POS. Explainable sales pitch ("increased due to heat + campaign").

Distributor:

Replenishment window and route allocation with realistic targets. Fewer trips "in the dark.".

Management:

Alignment between Trade, Sales, and Logistics. Reduced reliance on sentiment. A single plan from industry to POS, with clear drivers (climate, revenue, promotion, media, and events).